Jiangsu dade heavy industry co ltd.

Amada laser cutting speed chart.

I was having trouble finding dade heavy industry but looks like these guys.

Incorporating fiber laser cutting technology helps users process a variety of tubing and pipe with greater speeds compared to a co2 system.

See separate sheet for break in cutting cutting time.

Most of the information from the big 2 4kw units does not directly apply much like using a haas vmc feed and speed chart does not directly apply to a tomach.

The examples of the adjustments made will be similar for any co2 or fiber laser cutting mild steel with o2.

I bought a used amada lc 2415 alfa iii nt.

The differences in the operating cost are based on the maintenance and the efficiency of the style of laser being used.

For the last two weeks i ve been cutting material 8 hours a day.

Factory cut chart settings.

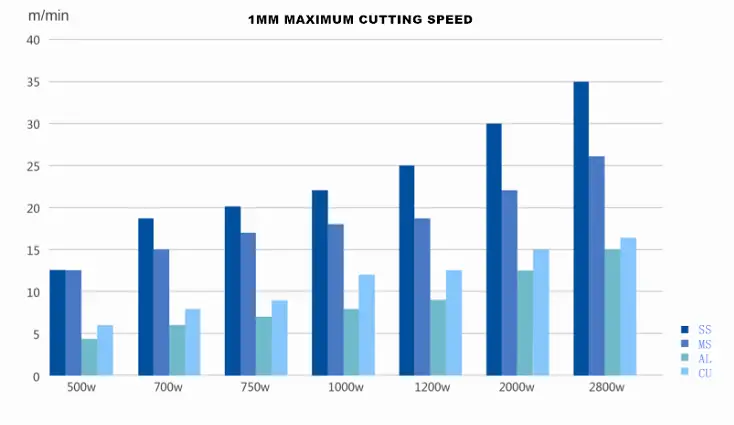

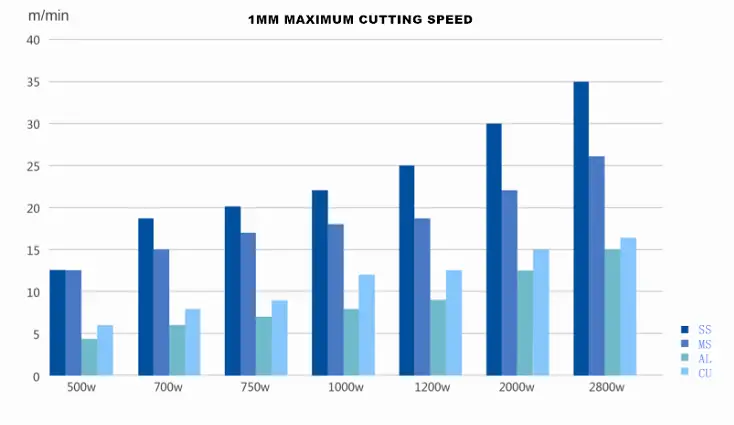

The final piece of the puzzle for laser processing is the cutting speed.

2kw i have no prior experience with laser cutting machines but i m a fast learner.

Different fiber optics material quality gases optical lenses cutting patterns etc will affect the cutting speed and need to be adjusted according to site conditions.

If for example the cutting condition is e010 it implies scribing and not piercing.

Set the blade speed referring to the chart below.

Feed rate is the speed the laser cutting head moves at.

Referring to the cutting rate given in the chart below adjust the cutting speed so that the cutting time calculated as described in the page on the left can be obtained note.

The following show 12 6 and 3 2 mm 1 2 1 4 and 10ga mild steel cut with oxygen on a 2kw fiber laser and examples of the same part cut with 1 variable changed to show how it affected the cut quality.

Lf the blade is a new one perform break in cutting.

Chart 3 illustrates the different efficiencies for the various cutting lasers.

Laser cutting machine plasma cutting machine.

2 weeks ago i finally finished the installation and the amada technician here in israel came and did all the necessary procedures to turn the machine on.

Cutting conditions range from e1 through e10.

This column shows the actual feed rate during program operation.

Amada engineered the 3kw ensis 3015 ri to include an innovative rotary index with the power and speed to efficiently transition from flat sheet to tube or pipe cutting.

Amada fibre and co laser cutting machines designed to optimise your production amada s solutions for laser cutting have been designed to meet all your application requirements.