Different fiber optics material quality gases optical lenses cutting patterns etc will affect the cutting speed and need to be adjusted according to site conditions.

Amada laser cutting speeds.

Co 2 lasers use an electromagnetically stimulated gas typically a mixture.

Amada s fiber laser cutting systems and co 2 laser cutting systems range from 1kw to 9kw.

Given its dominance in the sheet metal cutting industry this article focuses on laser fusion cutting.

If you d like to learn more about ablative laser cutting check out this article on micron scale manufacturing.

Their advanced motion and.

The cutting capabilities of the laser is directly proportional to the beam quality and beam waste of the laser.

Very high quality stainless steel and aluminium processing is also achieved.

Their advanced motion and.

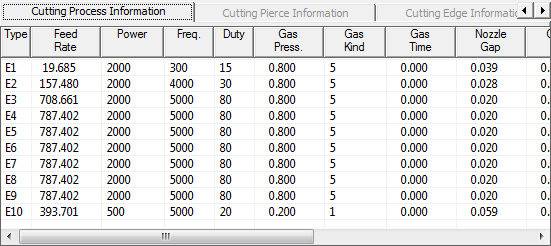

Cutting conditions range from e1 through e10.

The laser technology in amada laser cutting machines allows for high cutting speeds and the flexibility to process a wide range of materials like aluminum steel copper and brass resulting in process range expansion p r e.

The laser technology in amada laser cutting machines allows for high cutting speeds and the flexibility to process a wide range of materials like aluminum steel copper and brass resulting in process range expansion p r e.

The final piece of the puzzle for laser processing is the cutting speed.

Incorporating fiber laser cutting technology helps users process a variety of tubing and pipe with greater speeds compared to a co2 system.

This column shows the actual feed rate during program operation.

The following data in the laser cutting thickness speed chart is for reference only.

The ensis series achieves high speed cutting in thin material a key capability of fiber technology and the ability to process thick plate efficiently.

Feed rate is the speed the laser cutting head moves at.

The 3kw 6kw and 9kw fiber engines incorporate amada s ensis technology that optimizes the laser mode and beam parameter product bpp based on the material thickness being processed.

Approximately 80 of the time while the program is running the laser is cutting this is the majority of the processing time.

If for example the cutting condition is e010 it implies scribing and not piercing.

Amada engineered the 3kw ensis 3015 ri to include an innovative rotary index with the power and speed to efficiently transition from flat sheet to tube or pipe cutting.

Fiber lasers vs co 2.

The two most common types of laser cutting machines are fiber laser and co 2.

Amada s fiber laser cutting systems and co 2 laser cutting systems range from 1kw to 9kw.