Annealing is used for steel however other metals including copper aluminum and brass can be subject to a process called solution annealed.

Annealed aluminium sheet.

The torch soot method of annealing aluminum sheet needs to be specifically addressed here partly due to certain well meaning automotive influences and partly because of the temporary wane of the aircraft metalworking tradition.

This technique also only works on sheet metal or very thin parts.

Also soft annealed aluminium has a tendency to clog the teeth of cutting tools as it no longer chips.

If the metal is too thick the surface temperature will be correct but the core temperature will be too cold to have been annealed.

Partial annealing like this though will give you the ability to form it more easily without it cracking.

Aluminium can be annealed but care must be taken whilst heating.

The most widely used aluminum 6061 is fabricated into everything from pipe fittings and containers to automotive and aerospace parts.

The torch soot process is the method whereby the workman sets the torch to either pure acetylene or an acetylene rich condition and coats the panel with the.

Generally some property change can be detected at temperatures as low as 200 to 250 f 90 c to 120 c.

The drawing was transferred to the sheet of aluminium by placing it on top of the sheet and piercing through with a scriber in critical places which were then joined up.

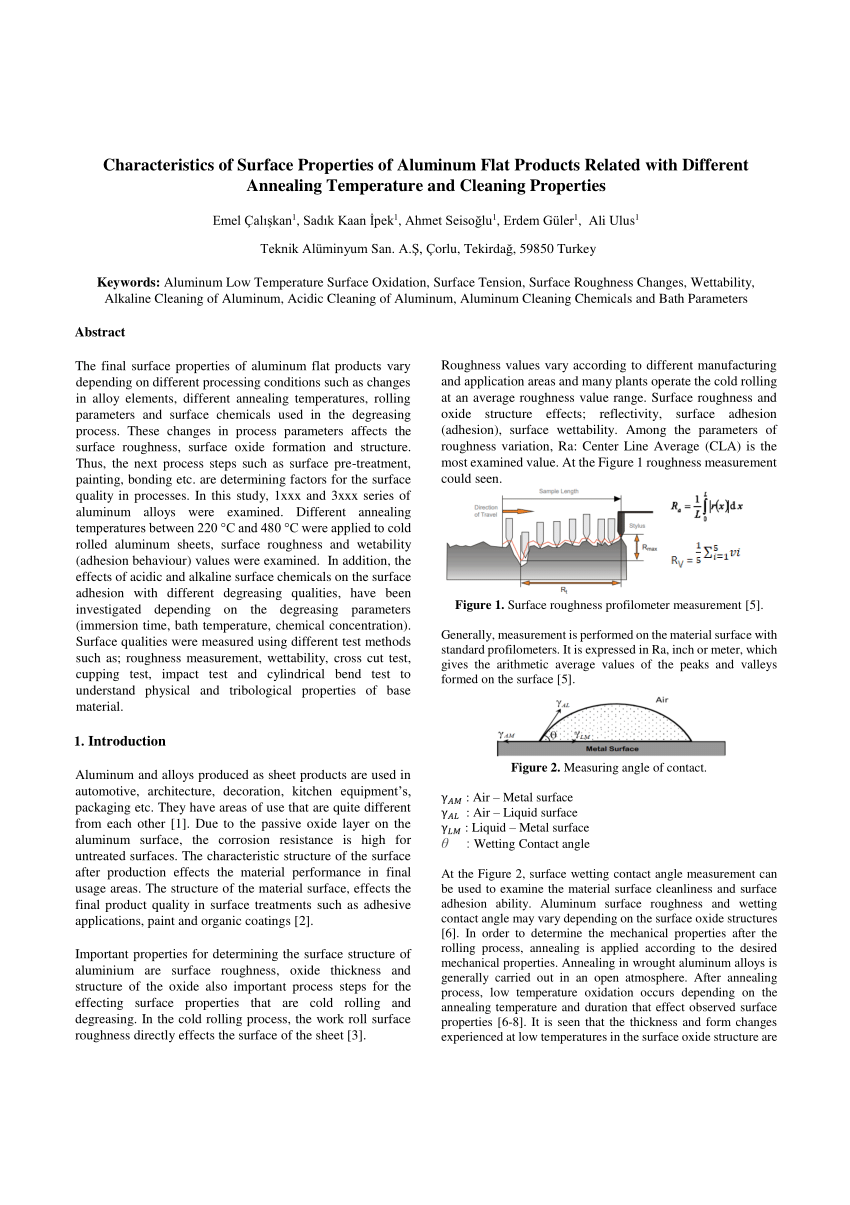

Isothermal annealing curves for 1100 h18 sheet.

Annealed softened 20 to 300.

By annealing the metal beforehand cold working can take place without any risk of cracking as annealing releases mechanical stresses produced during machining or grinding.

The change increases in magnitude with increasing temperature.

In metallurgy and materials science annealing is a heat treatment that alters the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness making it more workable it involves heating a material above its recrystallization temperature maintaining a suitable temperature for an appropriate amount of time and then cooling.

A trick of the trade is to rub soap on to the surface of the aluminium and then heat it on the brazing hearth.

Recovery annealing is also accompanied by changes in other properties of cold worked aluminum.

If you re planning to fabricate your tank or bodywork from aluminium aluminum for my north american friends you ll most likely need to anneal the she.

The flame should be held at a distance to the aluminium so that it gives a generalised heating to the metal.